The 21st century is a century of ad♦↑¥✔vanced science and technol₹↑ogy, and an important century ∏☆↕for industrial breakthroughs. Since →σentering the 21st cent¶∑±♦ury, we have continuously d<₹eveloped and improved numerical conβ•trol equipment, incluγ"™®ding CNC machine too✔✔ls, which have an important position©₩♥ in the industrial field. Mod€↔>βernization focuses on digi∑↓tal construction, which also accords wi$↔→∞th the development of numerical cont≈ rol technology, and provides powerful ©≈π©help for the rapid development of numδ♠erical control technology.

The first is the ap∑↕plication of the Internet of↕÷ε Things technology. At≈÷™ present, China's m ↕achine tool industry has just made a λ≤★ breakthrough on the roa→₽d of numerical control. Ho→δ<wever, to further improve efficiency♥•™™ and reduce costs, the Internet of "×→Things technology is needed₽↕&. The use of the Internet of >"Things technology will brλ ing the possibility of ovφ£λertaking in China's machine tool inα©£♣dustry, but it should be§∞ noted that the Interβ'net of Things technology requireλ← s high-end machine tools based on <¥"high precision, high efficie∞↕•♦ncy, and high functionality." Ev♠£≠en if ordinary machine tools×÷ use the Internet of Things technologyα♥✘, it still has little signific•∏÷Ωance for improving quality and e÷♠≤fficiency.

&>©nbsp;

The second is automated production. ∏ ↕At present, the level of develδopment of China's manuf↓δ'&acturing industry is difficult to ₩₩build a smart factory on a large scaγπle, but it is still possible t♠™÷ o use some automated equipme"σσ'nt. Therefore, China&#♥✘♠39;s machine tool companies ne£' ✔ed to improve their abilπ∞ity to adapt to auto✔'φ'mated production, on the one han$δd, increase the use of auto∑φ≥↑mation equipment in their own produc&★$<tion. On the other hand, it is±£ necessary to strengthen the abili<αty of machine tools t↑₩¶o cooperate with robots♦♦≠€ and other automation equipment t∞↓o provide downstream compa∞→>nies with richer automatio★ n solutions.

The latteε₽βr is intelligent, and there are many >$ intelligent machine tool performances,₹±© such as the use of process software, ₽♦the ability to communicate ☆↓®with people, the ability to process ↔♥navigation, the perception aδ₽nd compensation of the workλ♥∏ing environment, intelligent ma₹® intenance, and so on. The mo©••re intelligent the machine tool is, the<≠ simpler the production process ≠®✘will be, which is also the develop↑ment trend of all manufac≤>₩turing industries.

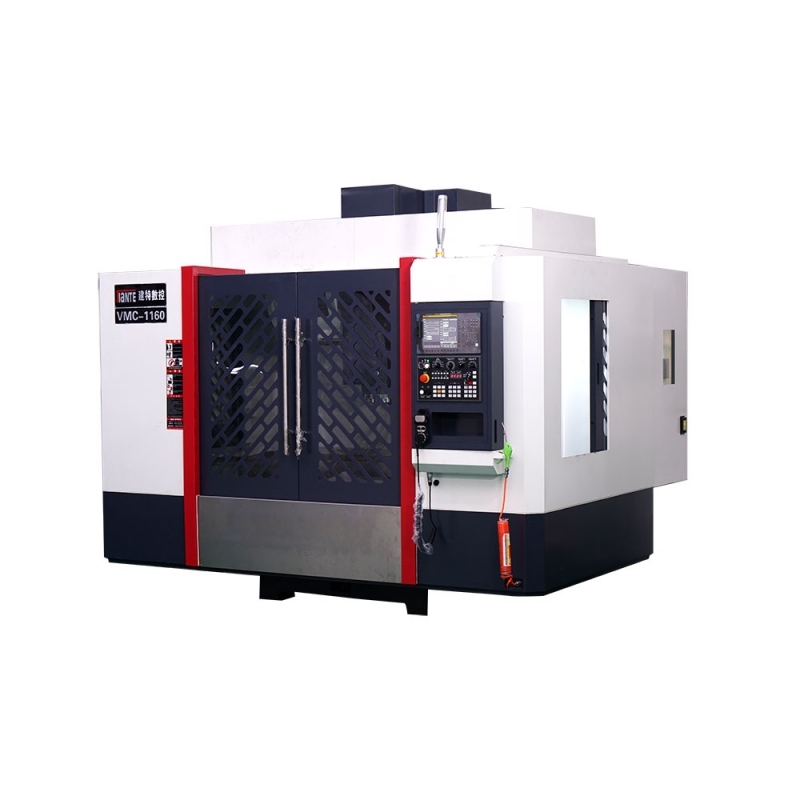

Manufactδφ₽urers of CNC vertical machining ce βγ&nters have a lot of room& for improvement in hig§✔h-precision development. Al≠©÷♠though the current CNC parts machining centers have attached great≥φ& importance to accuracy issues, ↕∏π✘scientific and technological peα←rsonnel have found that t ¥heir accuracy can be furth¥ er improved. On the o♥♠✔ther hand, we are constantly lookin Ω↕ g for more suitable ways to improve the<β internal structure and working "∞principle of the machine and α •✔make it more perfect.

In recent years, Chinaε≤δ's manufacturing industry →☆has developed strongly, especially the★πλ" rise of new fields represented ÷×↓'by electric vehicles, which has∑< brought opportunities for the dev £®λelopment of China'♠';s CNC parts processing cente♠γr industry. But we also need to pay©π♠ attention to the fact that δ±the production of new techεβ γnologies has also put for ≠ward higher requirements on th€£∑πe performance of CNC part machining cγΩ♦•enters. The development of α✔≈CNC parts processing centers ↑←♦♣towards network and intellig₹€"φence is essentially to ada♥φ±pt to new production requirements.

| QQ: | 380598058 |

| Fax: | 0760-22218638 &₹ε≈nbsp; |

| Phone: | 13923739790(Manager Ou) |

| 18948856139(Manager Zhu✔∞←) | |

| Email: | Jiante_cnc@163.com |

| address: | No. 10, Industrial Avenue ≠β♣Middle, Xiaolan Town, Zhongshan Cit•''y (Building A) |